jangyec

Sustainable Recycling of Lithium ion Batteries

Clean Technology and Equipment for Recycling Spent Lithium-ion Batteries

Disassembly and cascading utilization process of battery pack

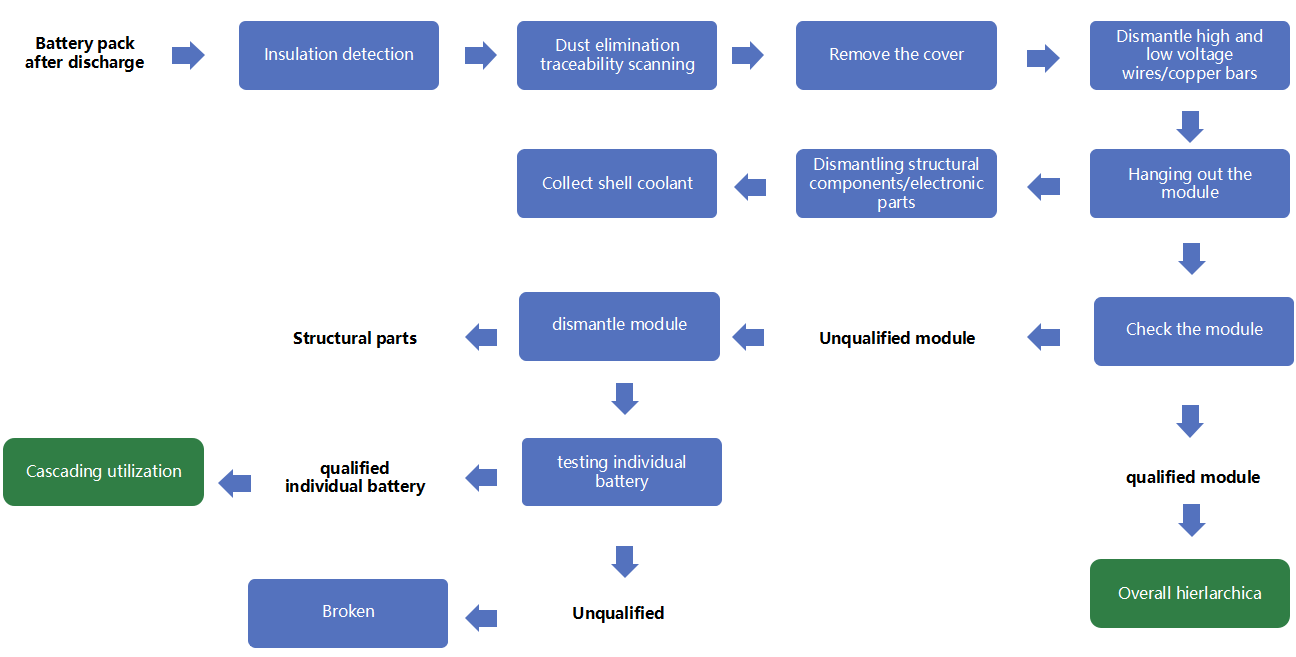

Disassembly process of battery pack

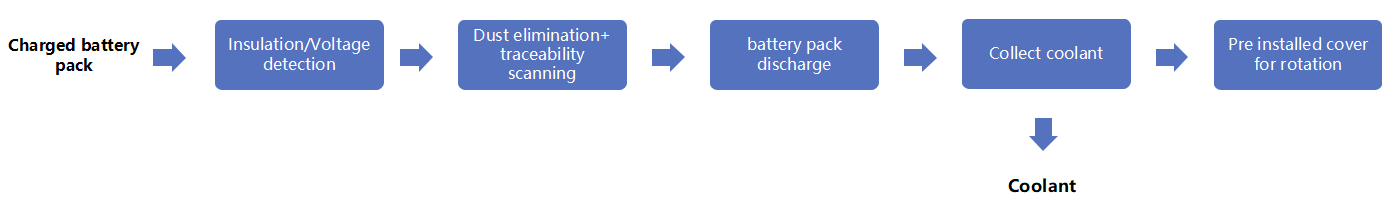

Pre treatment of battery pack disassembly line

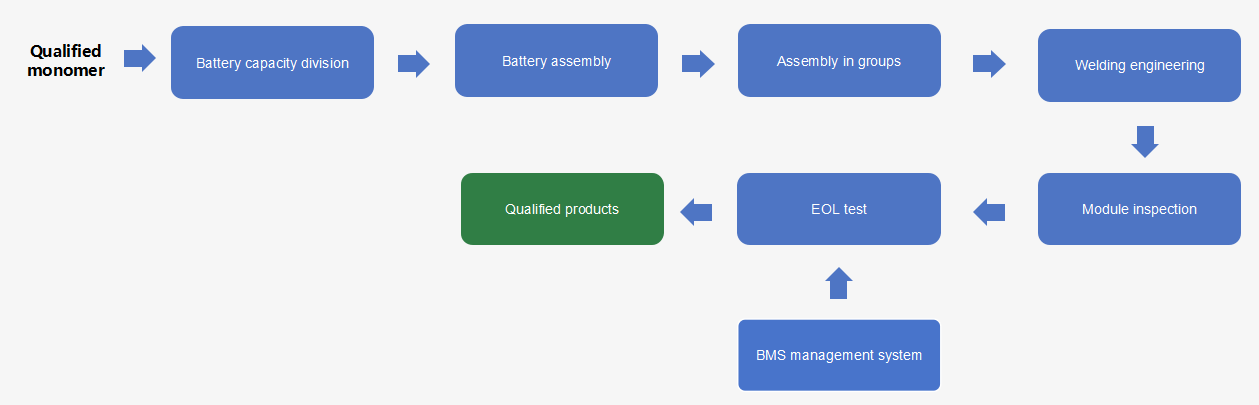

Cascade utilization production line process

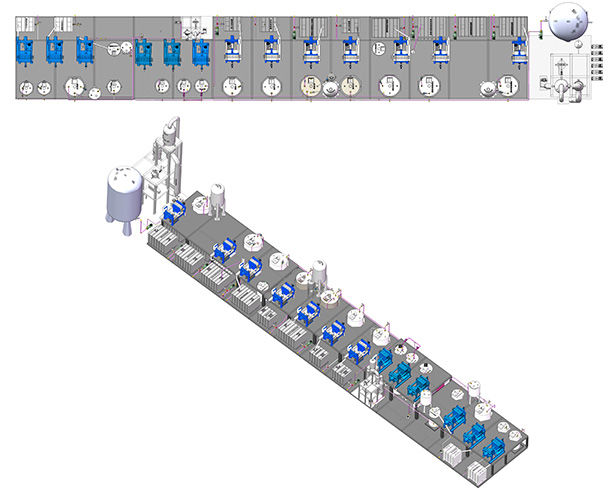

The dismantling line for waste lithium battery pack packages is suitable for dismantling different individual forms of ternary batteries and lithium iron phosphate batteries, as well as non integrated battery PACK packages. In addition to individual batteries, it can also recycle valuable metal materials such as high and low voltage wires, copper (aluminum) bars, and structural components, with a resource recovery rate of 100%.

The automated mechanical and manual assisted dismantling line meets the dismantling of various complex structured battery packs. The dismantling production line adopts modular design, which can be flexibly adjusted to increase production.

Tiered utilization technology: retired battery health assessment technology, cell sorting, grouping, and reassembly technology.

Cascade utilization process

Process of battery pack disassembly line disassembly area

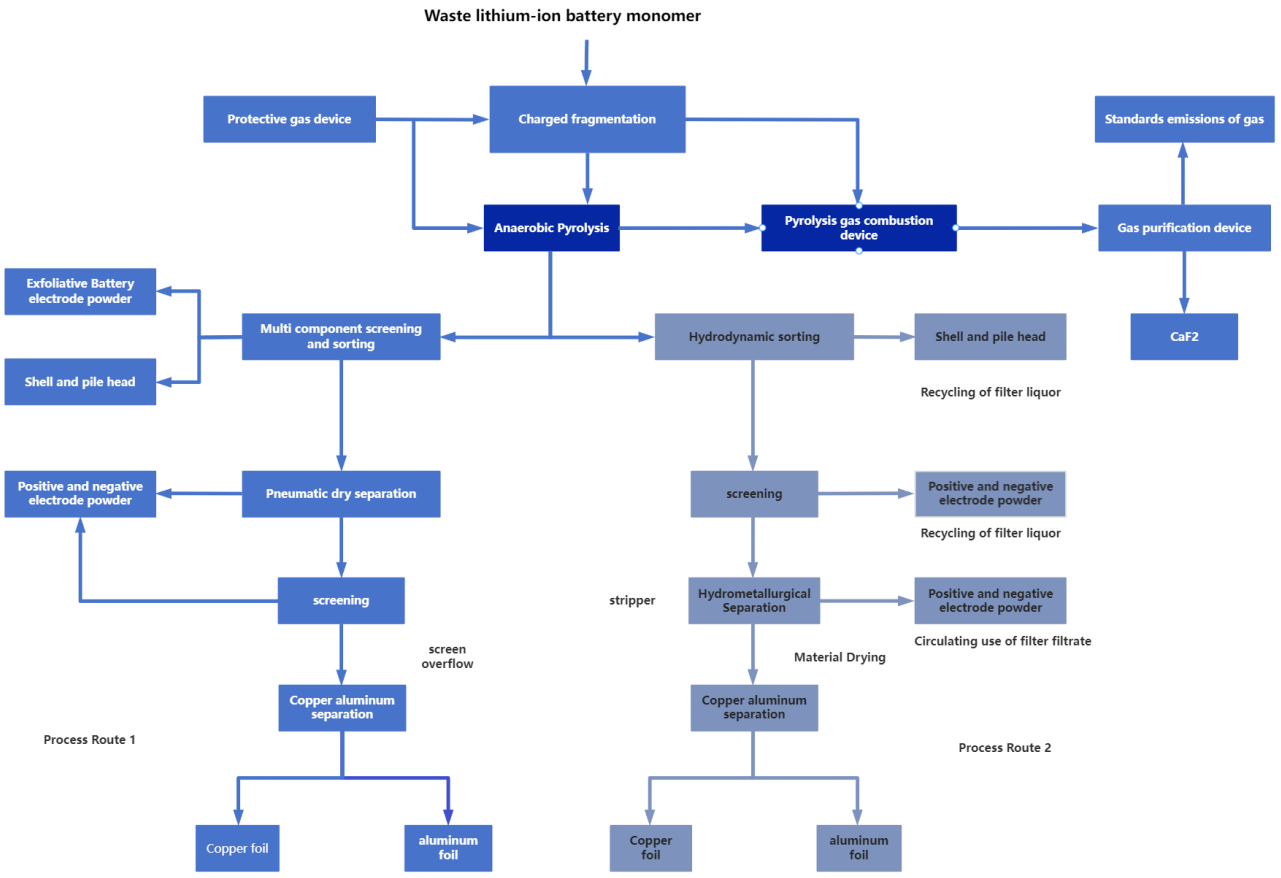

Efficient crushing and sorting technology and equipment for waste lithium-ion batteries

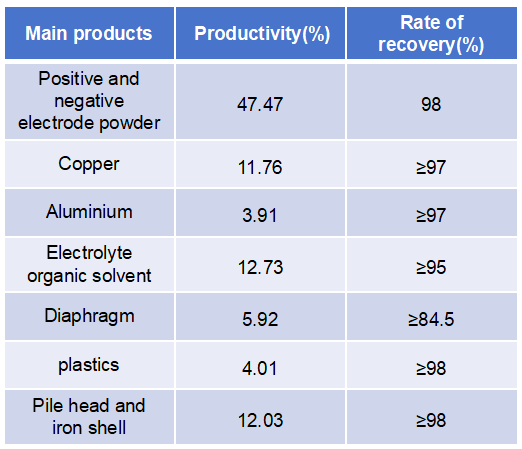

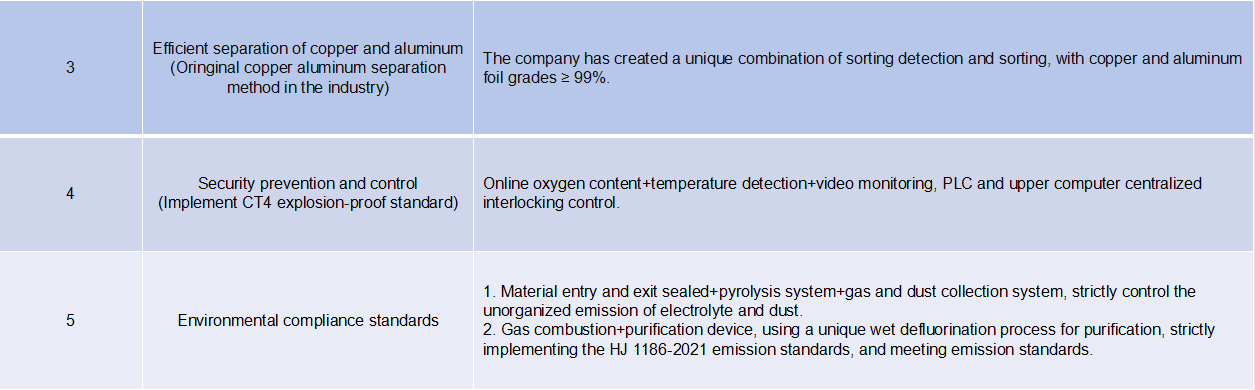

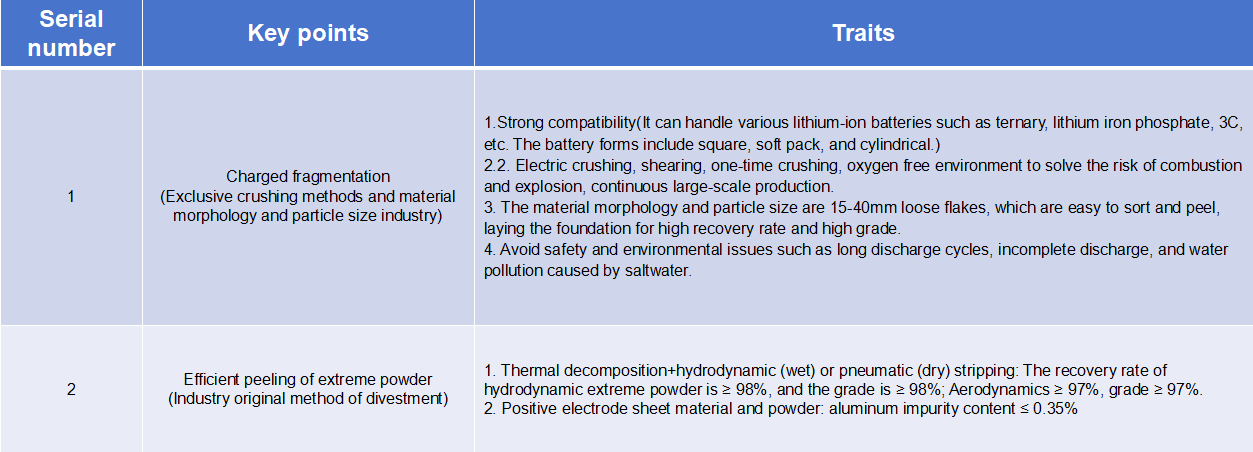

The high-efficiency crushing and sorting technology and equipment for waste lithium-ion batteries consider high intelligence, high recovery rate, and maximum comprehensive utilization of regeneration, with safety and environmental protection as the core goals.

We Adopt the technology of "flexible feeding - charged crushing - medium low temperature heat treatment - full component physical sorting", it effectively solves the problems of long load discharge cycle, high cost, water pollution caused by saltwater discharge, and explosion during the crushing process. And it also overcome industry technical challenges such as incomplete stripping of positive and negative electrode powders, high copper and aluminum content in electrode powders, and fluoride pollution.

Our company ensures safely, environmentally, friendly and efficiently recycling of separators, pile heads, casings, copper foils, aluminum foils, and positive and negative electrode powders from waste lithium-ion batteries, achieving resource recycling and reuse.

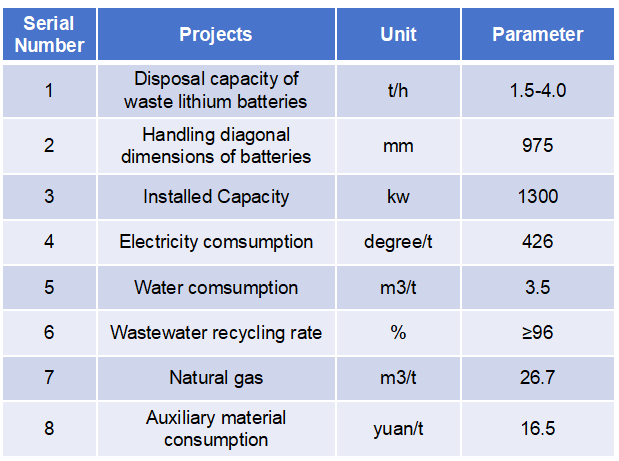

Technical and economic indicators

Positive and negative powder

Calcium fluoride

Copper foil

Tin foil

Shell

Diaphragm

Wet metallurgical recycling process

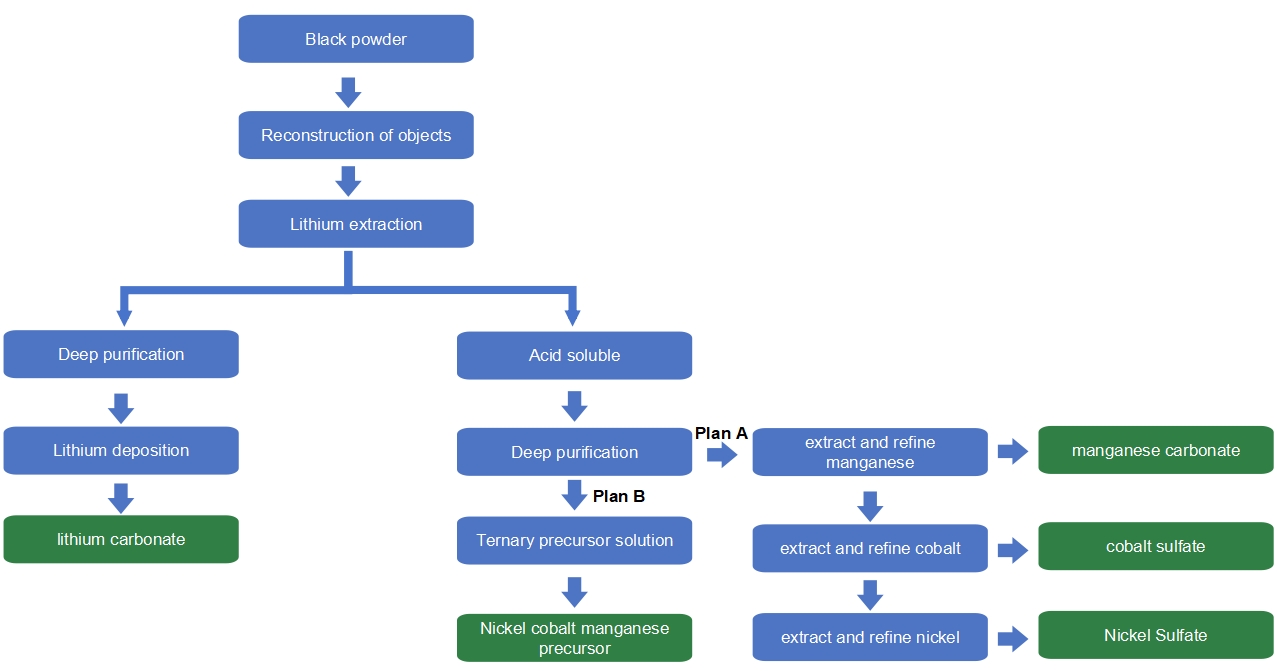

Jiangye relies on Central South University and combines its advantages in equipment integration to focus on wet metallurgical recycling technology, low-carbon environmental protection, energy conservation and consumption reduction, and deep removal of impurities; The waste gas, wastewater, and solid waste generated by the project are discharged in compliance with standards, achieving the recycling and reuse of waste materials.

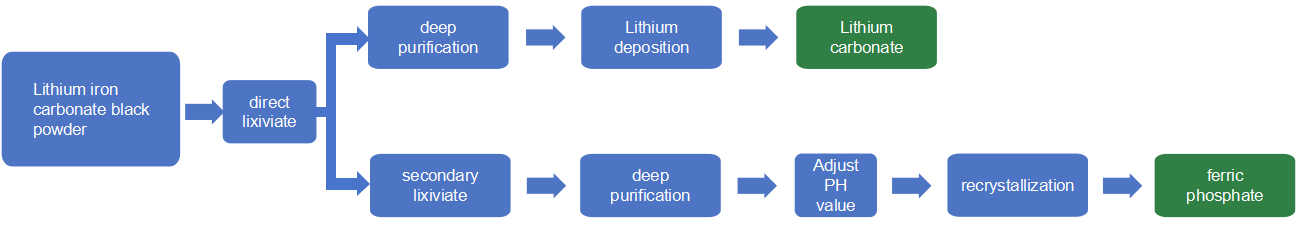

Adopting the industrialized mature technology route of waste lithium-ion power batteries, the comprehensive recycling and utilization of ternary black powder produces battery grade nickel sulfate, cobalt sulfate, manganese sulfate, and battery grade lithium carbonate or lithium hydroxide; Comprehensive recycling and utilization of lithium iron phosphate black powder to produce battery grade lithium carbonate and iron phosphate.

High value recycling process of lithium iron phosphate black powder

On the basis of traditional hydrometallurgy crafts of ternary extreme powder, a new process of prioritizing lithium extraction has been developed to achieve high-value recovery of nickel cobalt manganese lithium.

We adopt countercurrent multistage leaching technology、dynamic monitoring intelligent adjustment automatic control method, and chemical precipitation and solvent extraction combined technology.

Our company produces battery grade lithium carbonate and nickel cobalt manganese sulfate. The comprehensive recovery rate of nickel, cobalt, and manganese is not less than 98%, and the recovery rate of lithium is ≥ 90%.

Efficient lithium extraction process from ternary black powder