Sustainable Recycling of Lithium ion Battery

JIANGYE specializes in the responsible and sustainable recycling of end-of-life batteries. Leveraging state-of-the-art technologies, we recover CRM(Critical Raw Materials) safely and efficiently while minimizing environmental impact. Driven by our commitment to sustainability, we pioneer closed-loop recycling solutions through advanced processes and proactive resource conservation—empowering industries and paving the way for a greener future.

Jiangye offers innovative solutions with a focus on sustainability and efficiency, positioning itself as a competitive alternative to established EU supplier.

While there are areas for improvement,particularly regarding regulatory compliance and long-term support, Jiangye's contributions to the field are

significant and worth considering for those prioritizing cutting-edge technology and environmental responsibility.

INPUTS

Jiangye process is effective for the treatment of all types of battery wastes: modules,cells, small packs and production scraps.

Suitable for every cells chemistry and geometry

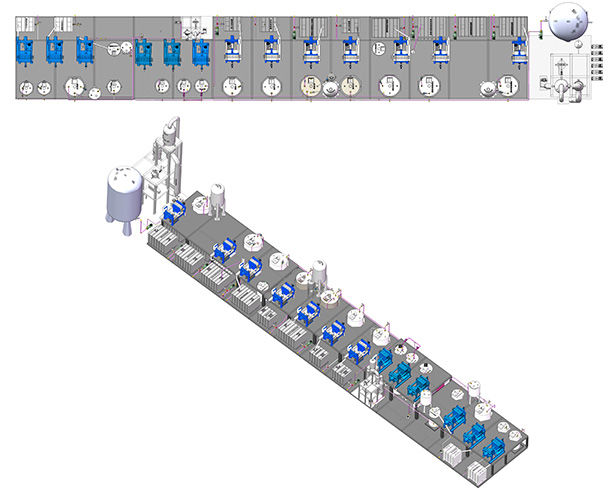

Unique shredding & Material Separation Technology

Charged shredding,

- Continuous Pyrolysis/Evaporation,

- Nitrogen Atmosphere,

- Solves the risk of explosion, enable continuously mass production.

Low environmental impact.

OUTPUTS

Recovery Rate: 97%

Purity:up to 97%

Copper Granulates

Recovery Rate: 97%

Purity:up to 97%

Cu/Al in BM: <2%

Recovery Rate: 92%

Purity:up to 90%

Al Granulates

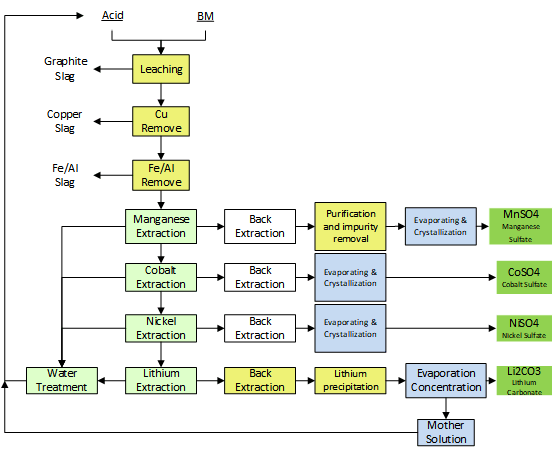

Black Mass Hydrometallurgy

- Nickel Sulfate,

- Cobalt Sulfate,

- Manganese Sulfate

- Lithium Carbonate or Lithium Hydroxide

Typical NMC Hydro-metallurgy route: outputs: Li2CO3 , NiSO4 , CoSO4 , MnSO4

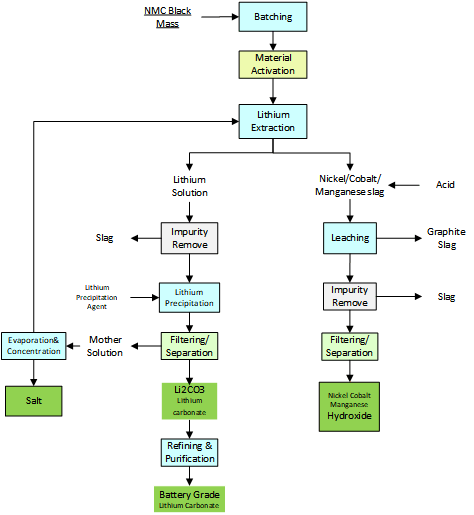

NMC Preferential lithium extraction;

Main products: Li2CO3,

by-products : Nickel/Cobalt/Manganese Hydroxide.

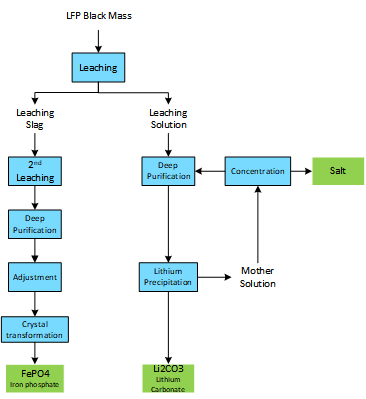

LFP Hydro-Metallurgy, Products: Li2CO3